2/28/2022 – 3/13/2022

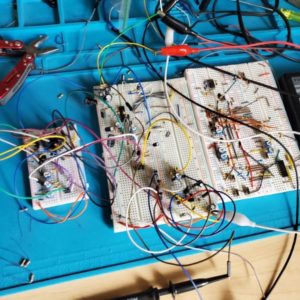

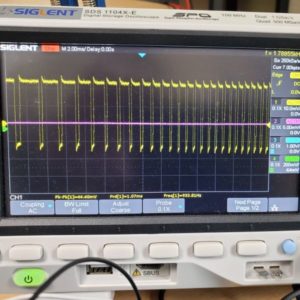

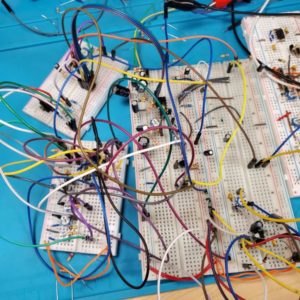

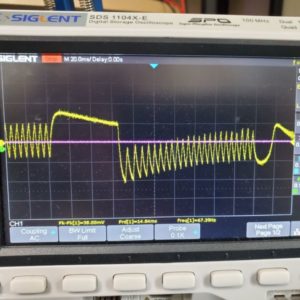

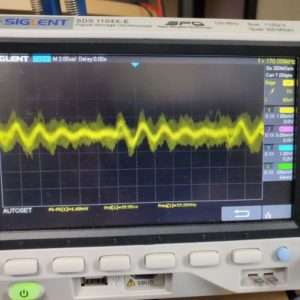

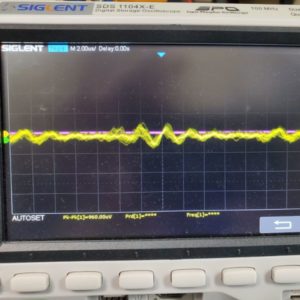

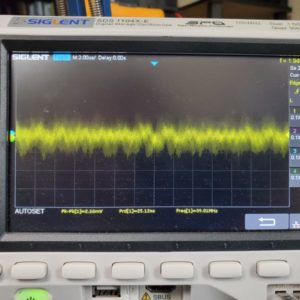

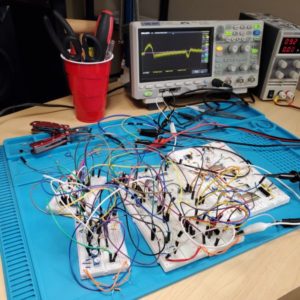

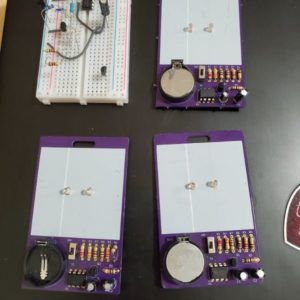

Summary: My goal for this two week block was to finish debugging the breadboard synth, make any design changes necessary, and then route and order the PCB. I got called to go onto a job site though both weeks this sprint so I lost a lot of productive lab time. My 555 Badge PCBs did show up though, and I soldered them together and figured out how to use my Dremel to trim the sides they don’t scratch people when they handle my boards. The Breadboard Synth is functioning how I expect it to now, and I can consistently recreate the Radio effect by simply disconnecting the input signal pot and placing my finger, or a screwdriver with my finger attached, to the input signal line.

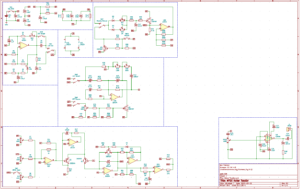

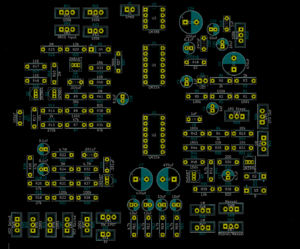

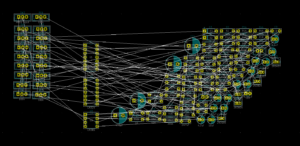

I did make some design changes to the schematic for the synth and assigned all the footprints and began routing. I’m having trouble figuring out a methodology for routing larger boards with more than 10 simple components. I’ve got two 14 pin opamps to route to and it’s becoming a confusing task to try and make a layout that doesn’t just look like an actual ratsnest/mess.

Soldering together the PC boards make me realized I don’t actually know any advanced soldering techniques. I’m pretty good at getting a good glob, but it occurred to me that it’ll probably be worth my time to spend some time soldering together some kits and figuring out how to use SMT kits, desoldering, resoldering, etc.

No 3D Prints/Modeling this week, but I did buy some new red PLA filament because I ran out of the black after a spaghetti incident.

I also spent some time planning out a friend’s office space. He needs some help installing some smart home type stuff, mounting some LED strips, building a desk, and building and lighting a display cabinet. That’s not something worth posting in further detail at the moment.

I’ll be doing field work the second week of F as well, so I anticipate there will be more interruptions for F as well. Once the synth PCBs are ordered, I’m switching gears to Monty’s Interview Questions for a bit before moving on to the Power Supply PCB. Originally, the synth was supposed to be a warmup to the PSU, but I’m guessing the PSU will be easier than the synth at this rate. Either way, I’d like to take a short break from KiCAD and its various frustrations and just check some boxes. Along with the Interview Questions, I’ll take some time to practice soldering skills and maybe model out a new soldering iron holder that can affix to my desk. While assembling the 555 Badge boards, I left the soldering iron on too long and the washer I had hot glued to a 3D printed holder warmed up and melted the hot glue, rendering the whole thing useless.

Eagle

Resources List

Monty Choy Hardware Interview Questions

1

Digital Design HQ Discord #Resource Dump

2

EEVBlog Power Supply Design Series

3

Intel FPGA Technical Trainings

3

Digikey intro to RTOS

4

Digikey intro to FPGA

4

Digikey intro to KiCad

4

FesZ intro to LTSpice

4

Tutorial Sites

Asicworld

ZipCPU

Nandland

cplusplus

Practice Problems for Hardware Engineers.pdf

FPGA4Fun

Nandgame

HDLBits

EDAPlayground

FPGA4Student

Bitsolver

5

Art of Electronics

5

Automate Boring Stuff with Python

6

C++ for Embedded Systems

6

3D Printing Dive

7

FreeCAD Tutorials

7

Timeline

January

A

3D Printer

B

3D Printer

February

C

Power Supply

D

Power Supply

March

E

Power Supply

F

Interview Questions

April

G

Interview Questions

H

Intel/Quartus

May

I

Tutorial Sites

J

Tutorial Sites

June

K

FPGA Projects

L

FPGA Projects

Interview Questions

4 weeks

Intel FPGA

2 weeks

FPGA Projects

4 weeks

Power Supply

6 weeks

3D Printer

4 weeks

C/C++/Python

Verilog

Art of Electronics

Synth R1 PCB Layout

After adjusting the schematic with the changes I found and discovered on the breadboard, it’s time to assign footprints and get moving on the board.

I’m about two weeks behind schedule now due to having to spend the last two weeks out in the field for work, and because I decided to include the Synth as another project before moving onto the power supply. Once the power supply is finished, I’m going to pore through the interview questions, and that should be sufficient to conclude the bootcamp and move on to something more specific

I do find myself wanting to push through and get through all this so I can read AoE cover to cover. I’m gonna have to do it eventually.

List of changes:

Removed input/bias resistors from pin 3 of LM386

Changed VCO depth for voltage source to 47k

Removed Sync Effect switch and set up simple voltage divider on VCO

Flipped Bypass capacitor on LM386 orientation

Deleted VCA

Deleted WNS

Now it’s time to lay out the footprints

Switches

Toggle Switch

https://www.amazon.com/MTS-101-Position-Miniature-Toggle-Switch/dp/B0799LBFNY/ref=pd_bxgy_img_1/146-9475865-9998724?pd_rd_w=RWoFK&pf_rd_p=6b3eefea-7b16-43e9-bc45-2e332cbf99da&pf_rd_r=37BBPKJACKR5SSPRGD5K&pd_rd_r=fb22504d-e1b7-4af9-9c06-284bf44bdfc6&pd_rd_wg=0sg0Y&pd_rd_i=B0799LBFNY&psc=1

Rocker Power Switch

https://www.amazon.com/dp/B08DKDWKPY?pd_rd_i=B08DKDWKPY&pd_rd_w=7GHH4&pf_rd_p=cc7afcc5-25bd-41a6-9934-4067a293ee62&pd_rd_wg=LyEq9&pf_rd_r=SZESXNAXYMBE93ZTZWDG&pd_rd_r=9f397944-0fd8-43dc-8423-9f246b4bff4e

this one has 2 pin ON/OFF, 3 pin ON/ON and 3 pin ON/Off/ON

10, 11, 101

Switch List

Power Switch: 10

LFO Shape: 10

VCO AREG Input: 10

LFO Select: 11

AREG Repeat/Manual: 11

VCF Select: 11

VCF Source: 11

Totals

11: 4

10: 3

For the footprint on the switches and pots, I can’t just find the pot itself. I’m going to have to run wires off the board up to the front panel.

So I’m thinking I’ll have to design footprints specifically for the wiring jump

It’s either that or I use the JST connectors I used on the 3D Printer. Mount female ports and then attach male ports to the potentiometers. That would make the whole system just a bit more modular and lend itself more to repairs

Checking the book for advice on cable management, signal interference, etc.

Nothing relevant in the book on signal interference. I don’t like the way he sets up the front panel at all

Potentiometer

1M: 3

RV4

RV7

RV8

100k: 7

RV1

RV2

RV3

RV5

RV6

RV9

RV10

Different Pot Link

https://www.amazon.com/OCR-Potentiometer-Assortment-9Values-Terminal/dp/B07YB11Q6W/ref=sr_1_6?crid=1TNCRHN4833I5&keywords=potentiometer+1M&qid=1646936875&sprefix=potentiometer+1m%2Caps%2C109&sr=8-6

https://www.amazon.com/HiLetgo-Single-Joint-Potentiometer-Variable-Resistors/dp/B00N1ZJ0JS/ref=sr_1_1_sspa?crid=1TNCRHN4833I5&keywords=potentiometer+1M&qid=1646936875&sprefix=potentiometer+1m%2Caps%2C109&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUE3Rk1OWU9KNFE4RkUmZW5jcnlwdGVkSWQ9QTEwMzU1MTcxT0dFNUNaSUFNTk1YJmVuY3J5cHRlZEFkSWQ9QTA5NzUxNTkxR0RRUEpJVTJPSDJPJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

https://www.amazon.com/HiLetgo-Single-Joint-Potentiometer-Variable-Resistors/dp/B07VJYH29F/ref=sr_1_1_sspa?crid=1TNCRHN4833I5&keywords=potentiometer%2B1M&qid=1646936875&sprefix=potentiometer%2B1m%2Caps%2C109&sr=8-1-spons&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUE3Rk1OWU9KNFE4RkUmZW5jcnlwdGVkSWQ9QTEwMzU1MTcxT0dFNUNaSUFNTk1YJmVuY3J5cHRlZEFkSWQ9QTA5NzUxNTkxR0RRUEpJVTJPSDJPJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ&th=1

https://www.amazon.com/Knurled-Insert-Potentiometer-Control-Switch/dp/B07F2768F5/ref=sr_1_4?crid=2SG8UXKNPSFRE&keywords=potentiometer+knobs&qid=1646936959&sprefix=potentiometer+knobs%2Caps%2C102&sr=8-4

Capacitors

Ceramic/NP Capacitors

5mm Lead Spacing, 7 total in the system

C8

1nF

https://www.digikey.com/en/products/detail/vishay-beyschlag-draloric-bc-components/K102K10X7RF5UH5/2356873

C9

100pF

https://www.digikey.com/en/products/detail/vishay-beyschlag-draloric-bc-components/K101J15C0GF5TH5/286496

C14

1nF

C15

1nF

C16

1nF

C19

1uF

https://www.digikey.com/en/products/detail/vishay-beyschlag-draloric-bc-components/K105K20X7RF5TH5/2820552

C23

470nF

Electrolytic/P Capacitors ( by module) (17 total)

4 5mm Spaced

13 2mm Spaced

PSU (6)

Ref

Val

Lead Spacing

C2

470uF

5mm

C4

10uF

2mm

C5

10uF

2mm

C7

470uF

5mm

C10

10uF

2mm

C11

10uF

2mm

AREG (1)

C17

4.7uF

2mm

LFO (3)

C1

1uF

2mm

C3

470uF

5mm

C6

1uF

2mm

VCO (1)

C18

0.1uF

2mm

VCF (2)

C12

0.1uF

2mm

C13

0.1uF

2mm

AA (4)

C20

0.1uF

2mm

C21

10uF

2mm

C22

10uF

2mm

C24

220uF

5mm

Spent a few hours routing the PCB. It’s the largest and most complex board I’ve tried to route so far. Everything I try to do feels like I’m just making a mess of the whole thing. I’m wondering what methodologies people apply to make themselves feel like they’re not just stringing everything together at random?

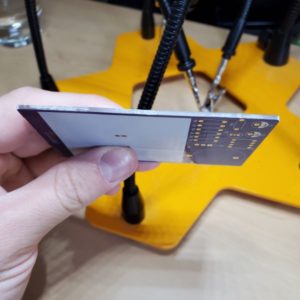

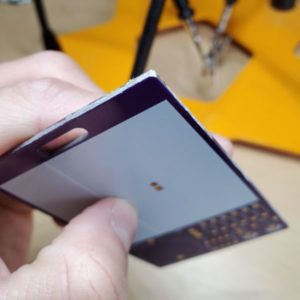

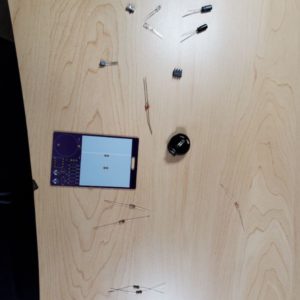

555 Badge PCB Build

I’m realizing I’m not actually very good at soldering and desoldering. I figured this would come up, but I should probably spend a few days to a week practicing advanced soldering techniques so this doesn’t become a point of frustration or limiting factor again. I messed up 2/3 boards and then made the third one with Angel and everything worked on the third one.

On the second one, I actually put the 555 in backwards, and it still managed to turn on, but wouldn’t do the fade animation the whole board was designed for.

For the first one, I had a bad 100k resistor that I didn’t check & test before I put it in, and couldn’t manage to get it out and put a new one into the hole, because I couldn’t clear the solder. So that’s the point that made me feel like I need to improve those skills some more.

I’m guessing it would be fun and worthwhile to just buy some solder-it-together kits for kids to practice. I also bought a SMT soldering practice board a while back, but I didn’t really take the time to learn to do it right.

Resoldering/Desoldering equipment, especially ICs I think is a core skill for making useful products out of scrap equipment