5/9/2022 – 5/22/2022

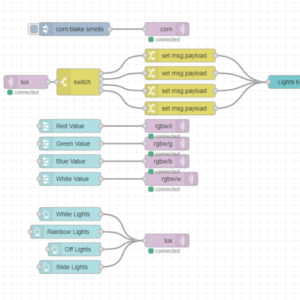

Breadnet Web UI (This controls my desk lights):

http://75.38.106.136:1880/ui

Summary: More pretty pictures. Fixed up Breadnet and got the core functionality out of it. Struggled with some data type conversions in the programming for the way the ESP32 handles MQTT payloads. Spent a lot of time tweaking things in VSCode until it worked exactly the way I wanted it. The code is super duct-taped together right now and needs cleaning up.

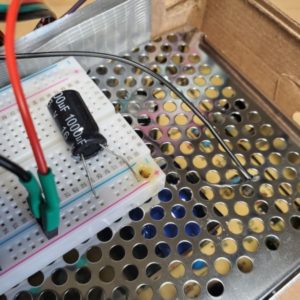

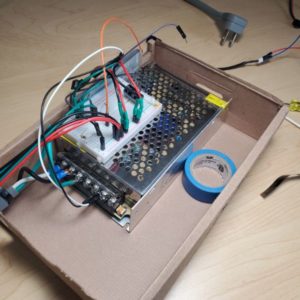

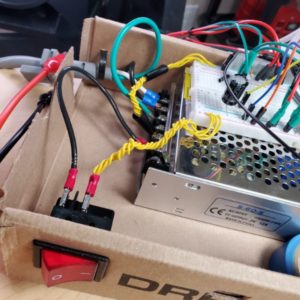

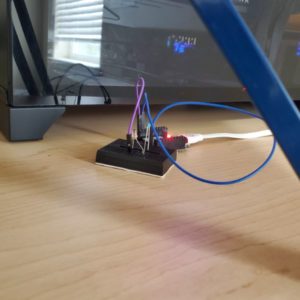

The Mega Lights controller box also had a huge fire hazard that melted the breadboard because I had about 30W of power running through two jumper wires whose terminal points on the breadboard were adjacent. No wonder it melted. The wiring issue is fixed and there’s a kill switch now. The Arduino replaced with an ESP and the lights can be controlled from the web UI.

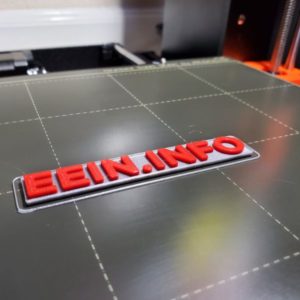

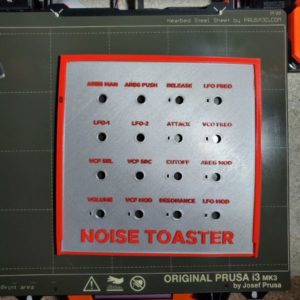

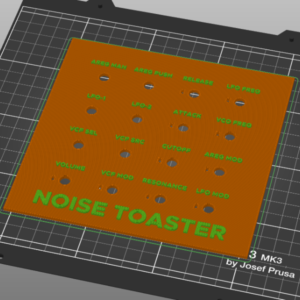

The Prusa printer works great. I tried tuning it but any attempt I made to calibrate it further just made it perform worse. After printing some full bed size sheets I can tell I should do the finer um-calibration because the front left corner is too close during print and creates rough textures. Other than that it’s incredibly plug and play.

Next sprint will be for wrapping up the Synth once and for all, after I jump through some hoops of figuring out how to design and print some mechanical features. Then printing and putting together a new lightsbox down the line. I might design a PCB for the lightsbox, but I’m not sold on the idea because it works fine as is for now. Also working on some new storage options and putting together my new soldering station. Playing with the idea of doing some Unity tutorials and making a game but that’s for later on.

Github Stuff:

https://github.com/fishPointer/MFOS-Noise-Toaster

https://github.com/fishPointer/ESP32-Blink-Test

https://github.com/fishPointer/ESP32-MQTT-Connection-Test

https://github.com/fishPointer/ESP32-Neopixel-Test

Jaguar

Jaguar Mode

Sprint Objectives

List of Projects

Breadnet

Deploy Something Useful on Breadnet

ESP32 OTA Updates

Finish Foundational ESP32 Script

Harden Breadnet Security

Set up a Breadnet Domain

Set up a basic MongoDB on the Pi for Node-RED to interface with

Mega Lights 2

Arbitrary control of 1 LED on ESP32

Equivalent Light Strip Script on ESP32

Design Lightsbox around ESP32 prototype+Color Text

Hack into my lightbulbs and control them with Node-RED

Gridfinity

Figure out where I could put them and what I would put

Can print a max of 4×5 no larger

Twizzles

Sharpie Holder

Soldering Station

Design new Soldering Station

Importing and Editing STL Files in FreeCAD

https://youtu.be/dr1qtaURrvI

Summary

Part Workbench

Import STL

Convert Mesh to Object

Refine Object

Convert Object to Solid

Switch to Part Design Workbench

Create Body

Add Solid to Body

Proceed with Edits

Steps

1

Create a new FreeCAD Document

2

File > Import > .STL file

3

FreeCAD imports the STL file as a Mesh. Convert the Mesh to an Object that can be worked on by switching to the Part workbench, selecting the mesh, and running Part > Create Shape from Mesh. After running this, delete the original mesh

When this happens, it has to “sew” together many polygons at a specific tolerance to form the object. The highest precision allowed is 0.01 mm

This creates a high poly render of the mesh as an editable object

4

In order to get rid of redundant polygons, select the new Object model and run Part > Create a Copy > Refine Shape. This will simplify the surface dramatically. After running this, delete the original object

5

Now that the object has been refined, all that’s left is to run Part > Convert to Solid. This will create a copy of the object that can function as a solid. Delete the original, Non-Solid

6

Switch back to Part Design workbench, then create an empty Body in the project, and add the newly converted solid to that body as a Base Feature. From there, you can sketch, add pockets and extrusions, etc. And should be fully functional for edits

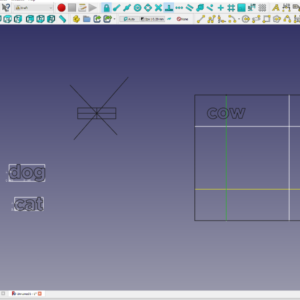

FreeCAD Wiki – Draft Shapestring Tutorial

https://youtu.be/_D5WJqd1SSE

I’m getting frustrated over text every time I try to use it

Back to CAD tutorials and taking my time to make sure I understand what’s actually happening

First, go into Edit > Preferences > Draft and turn off that god awful grid that won’t go away ever if you have show grid on when you open Draft for the first time

Second, create a primitive cube or something and go to Draft

Third, ensure the correct work Plane is selected

That’s the thingy that says “Top” and lets you pick the XY, YZ, XZ plane

Once the String is created, switch back to Part workbench and Extrude the ShapeString as is into a new solid

Make sure “Create Solid” is checked so it creates a unique solid

Switch back to the primitive, and go to Sketch workbench and create a sketch on one of the faces

Create an anchoring line and then switch back to the extruded text

Open the position properties and start incrementally adjusting it until it’s in place

After angling it to the correct Axis, switch back to Draft and get ready to snap endpoint move

Turn on the snapping mode, in this case endpoint snap

Then Select the extruded text body you plan on moving, and click the Move Command

From there, pick a point on the extruded text wireframe, and then select the point to snap to. In this case, the line created in the Sketch

Once snapped into place, you can verify that the extruded text solid is ready to be boolean cut from the primitive

Centering Text Tutorial

I have to write it myself

Switch to WireFrame or AS-IS view as necessary

1. Create a primitive

Make a cube or something in PART

2. Create grid for text anchor points

Go into SKETCH and make a sketch

Create intersections of lines wherever you want text to be centered and anchored

3. Convert the grid into draft lines

Switch to DRAFT and convert the sketch into draft lines

Select all of the newly created draft lines and UPGRADE them

Create a linked group of these upgraded draft lines for tidyness

Hide the sketch. If the lines were upgraded properly, they should be white instead of black

4. Create the text

Use the shapestring to create some text off to the side

Immediately switch to SKETCH and open a sketch on the plane the text is on

Reference external geometry to get the four outermost points of the string

Create a rectangle around the string and anchor the external points onto the rectangle to fully define it

Draw a single diagonal across the new boundary box

5. Anchor the text

Switch to DRAFT again and set snaps

Turn on SNAPPING and turn on MIDPOINT SNAP and INTERSECTION SNAP

Make sure the boundary box Sketch is visible

Select the ShapeString for the text and click Draft>Move

Select the midpoint of the diagonal via midpoint snap

Select the intersection point of the upgraded draft grid lines via intersection snap

6. Repeat for all Text

7a. Extrude Text

1/2

Go into PART and Extrude the ShapeStrings

Select the base feature of the body (the cube) and the extruded string

Boolean Cut

7b. Pocket Operation Text

2/2

Go into DRAFT and convert one or all of the positioned ShapeStrings into Sketches

Go into Part Design, select the Sketch(es) and Pocket/Pad operation

Desk Accessories

Design a Cable Holding Clip for Megadesk Midpiece

Phone Holder Slide Clamp

Megadesk Center Cover Card

Upper desk is 20mm thick

Shopping

Buy a Second Trash Can

Buy more Jumpers

Buy some helping hands that don’t SUCK

Look into keyboarding tools

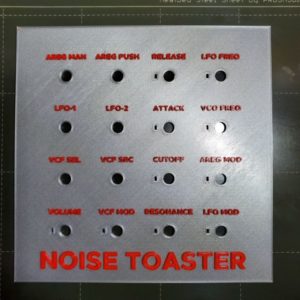

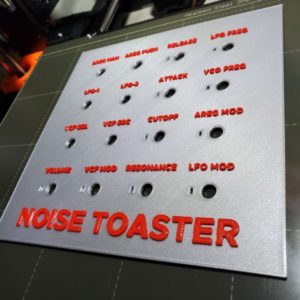

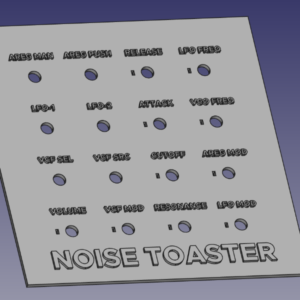

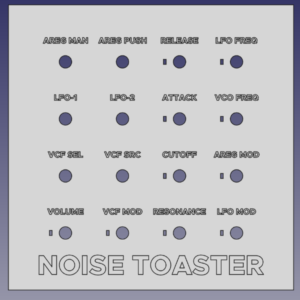

Noise Toaster

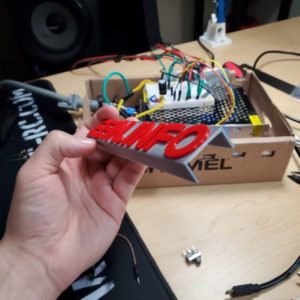

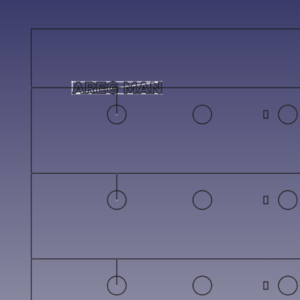

Multicolor Embedded Lettering in FreeCAD->PrusaSlicer

Redesign Synth Case

Timelapse Video – Soldering together second Synth

Mobile Power Supply

Mobile Power Supply Tutorial Series

Skilling

Unity Tutorials

Map C++ Resources

AoE Chapter 2

Monty Choy Interview Questions

Gridfinity

Links

*DOWNLOAD THE MODELS!*

📥 Divider Bins + Trays: https://bit.ly/3E6vNrR

👁 Window Bins: https://bit.ly/3OaI2YP

🍽 Baseplates: https://bit.ly/3781R2A

🖨 Printer-Mount Baseplates: https://bit.ly/38FOJ4R

🖨 3D Printer Accessories: https://bit.ly/3jtTfWu

📏 Caliper Holder: https://bit.ly/3EpMlv3

🔧 Ratchet + Socket Holders: https://bit.ly/3vcZ5B0

🔩 iFixit + ES121 Driver Holders: https://bit.ly/3xnsCdL

🛠 CNC Tool Holders: https://bit.ly/3KFjRj1

⚙ CNC Collet Holders: https://bit.ly/3JvubsE

⛏ Pick + Tweezer + Scraper Racks: https://bit.ly/3uD827I

🖊 Pen + Pencil Holders: https://bit.ly/3vaUCik

✂ Nippers + Strippers + Scissors Holders: https://bit.ly/3JFnRiu

Notes

Printing a 4×4 baseplate grid to start

With some little squares it fits great

I just, don’t know where I should put this or how big I should go…

NT – Noise Toaster

BN – Breadnet

Setting up on new router

Had to change all the 10.0.0.x back to 192.168.0.x

router pass g

After struggling to port forward anything, even a simple minecraft server, I looked up a list of common port forwarding issues, and one listed was that a lot of people don’t even realize they’re actually behind multiple routers. And so I installed a router counter and it turns out I am in fact behind two routers, the second one is mine, and the first is the AT&T thing in the garage

http://www.pcwintech.com/shanes-toolbox

My Router

192.168.0.1

ATT Router

192.168.1.254

Okay so

DLINK Router (mine)

Simple Port Forward

Just add a custom service to your IP

Device IP

ATT

Use Device Access Code found on back of router

Firewall

NAT/GAMING

Manage Custom Services

Create a Custom Service with the port you’re trying to open

Add the Custom Service you just made, and select the Device it’ll apply to

In this case, the device is the second router

192.168.1.65/unknownecade02eff78

Rinse and repeat for each port you’re opening

VSCode uploading to wrong port

You can specify which port you upload to

[env:uno]

platform = atmelavr

framework = arduino

; any port that starts with /dev/ttyUSB

upload_port = /dev/ttyUSB*

; COM1 or COM3

upload_port = COM[13]

Bare Minimum Breadnet Achieved

Raspberry Pi running Node-RED and MQTT

Port Forwarded

1880 for Node-RED

1616 for MQTT

ESP32 MQTT Connection Test

Setting up a fundamental script, making sure it’s clean, documented, capable, and commented so I can return to it in the future.

Not sure how to structure these notes for now but

in void reconnect(), make sure all topic subscriptions are in this

The first time the MQTT network is connected to is in the reconnect function which is called in loop, so technically there’s no setup for it

in void setupMQTT()

the setCallback function only gets called once and assigned once per mqtt instance, so I think everything has to be inside the singular callback function

So really, theres only three important functions in the program

void setup

void loop

void callback

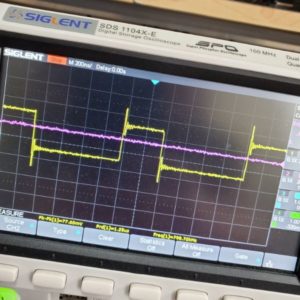

Speed Test

I ran an unconditional publish script to post “AAA” every loop and it posts very quickly. It can do about 10 posts/millisecond

so 10,000 posts a second? jesus

Topic Char* issues

referencing the char* that is the “topic” variable in the callback can’t be referenced to use the topic itself as a string for a future messages payload

meaning, I’m trying to make the payload for a response message to be the topic of the initial message, and it’s not working

Node-RED Booleans

Node-RED boolean switch outputs yield a string of ‘true’ or ‘false’

so instead, make the payload numbers of 0 or 1

MQTT Outputs

Binary-Ascii Characters Table

https://www.binaryhexconverter.com/binary-ascii-characters-table

The payload comes in the form of a byte

If you cast that byte as a string and print it to the serial, you’ll get the ascii code for that binary

example

payload: 0

instead of getting a string for ‘0’

you get a string in binary that represents the character zero

I can’t figure out how to get a number

MQTT passes ASCII data

so even number 0 results in 48

I can print back on ESP32 in Serial the payload byte and get 48

I can print back the char(payload) byte and get 0

but that’s still a char, I can’t get a numeral zero to work with

Success!

byte -> char(byte)

String(char(byte[n]))

int num = String.toInt()

Code

case 3:

Serial.println(payload[0]);

Serial.println(char(payload[0]));

//String popcorn;

popcorn = String(char(payload[0]));

Serial.println(“popcorn”);

Serial.println(popcorn);

shrimp = popcorn.toInt();

Serial.println(“shrimp”);

Serial.println(shrimp*5);

if(shrimp*5 > 12)

{

Serial.println(“you did it!”);

}

Waiting to upload to github until I clean it up more and demo it a bit, but wanted to write it down

It seems like I also need to convert the post-calc integer back into a char format in order to publish the results

Finally

server delivers a BYTE*

ESP32 takes BYTE* and converts it into a CHAR

then stores that CHAR into a String object

then String.toInt() to get an INT

then do math on that INT

then itoa() that INT into a CHAR

then publish that CHAR back to the server

Flag Colors

Red

176

5

5

Black

24

24

24

Grey

69

79

71

Green

0

242

98

ML2 – Mega Lights 2

ESP32 Neopixels

ESP32 works perfectly fine with copy/pasted code from the Arduino sketch for Neopixel control, which is good news

Unfortunately, the ESP32 can’t take 5V input. I think the max is 3.6 – 3.9V, so I need to find a way to lower the input voltage of the 5V supply.

I’m guessing that a level shifter is for control signals and not really for power transmission, so the best solution is probably to just use the other buck converter from the pack of two I bought for the old 3D printer

As I expected, the rainbow pattern is working, but it’s choppy and slow with mqtt running

I disabled MQTT’s client loop and just ran the pattern and it was nice and smooth again.

Having i print millis() after each light update cycle, it looks like they’re about

163 ms Light Cycle without MQTT

164 ms Light Cycle with MQTT

73 ms Light Cycle on Arduino

I think I might’ve just had the hue shift value at 32 still…. and that’s why it was choppy

ohh

I took .show() out of the loop so it doesn’t show after each pixel.

It seems like show is the longest part of the function, it’s so much smoother afterwards

I don’t remember messing that up, but now with show outside its

3 ms Light Cycle with MQTT

Verify ESP32 working with Buck Converter

I can’t tell if I should be plugging into VCC or 3.3 on this board’s pinout

I bought it on Aliexpress so its pinout doesn’t match anything else and I can’t really follow the traces visually

I’ve got plenty to spare though!

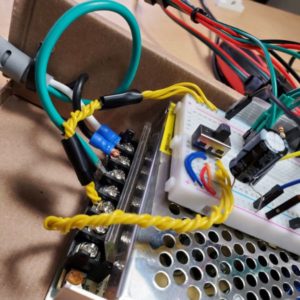

Melted Wires

There’s some intrinsic heat generated in the jumpers. They’re not meant to carry 2.5A.

Well, it kind of seems like they can handle it, but they used the breadboard as a heat sink

That, in combination with the breadboard being ON TOP of the power supply, and the voltage and ground wires being side by side, combined to make a very slow breadboard melting device.

Running it with just one or two branches of lights results in a tangible warmth coming from the wires. So, I need to do something about that

The best idea I can come up with as a temp fix right now is to just make sure the power and ground rails are on opposite sides of the breadboard, and then run multiple jumpers for each to diffuse the current.

And then tap them in at different points along the power rails, of course

Notes

i have all of the power running through a single jumper wire

and it melted the breadboard

so i need 2 wires

about 30W of energy if all lights are on, but it gets warm and compliant with just 1/4th of them

The lights flicker every now and then, not sure why

I can also distort the signal by putting hands on the wires

I’m guessing this whole thing just needs to be wired a little more securely

Lightsbox R-1

Took out the buck converter

It turns out that the ESP32 takes in about 5V from the USB when programming it, so why shouldn’t it be able to take 5V from a power supply?

I found that using the buck converter and inputting 3.3V actually interfered with signal integrity

I also figured out that the current limiting resistor of 400-600R is too high for the ESP

If you try to connect all 4 strips to a single PWM pin, the current draw is too much and the signal collapses. I had to reduce the R all the way to 100 for the signals to not crash

To in summary, increased input voltage to 5V (4.95) and decreased output resistance to 100R

I also found that braiding 4 solid core jumpers together solved most of the overheating problem. I still wanted a switch, so I inserted a breadboard switch, but it quickly became too hot to touch with all the current running through it, so I replaced it with one of the chunky breadbox switches I Had leftover. I had to crimp some terminals to get it installed but it was worthwhile and now nothing seems to overheat

I melt-tested by turning all the lights up to 255,255,255,255, which draws an insane amount of current.

The hottest thing in the box is actually the power supply at that point.

The connection between the crimped terminal and the breadbox switch that runs to the breadboard seems a little shoddy. I kept touching it to see how warm the braided cables are but it caused the lights to flicker off momentarily. If I do it too much and it turns off for too long the ESP also powers down.

For now, the lightsbox seems safe enough and I should be clear to move onto other things while enjoying the first practical application of breadnet and the fancy lights I put so much time into

I noticed a stuttering issue that I thought was due to the resistor being too high still, but it was regular. I correctly guessed that sometime during the mqtt check loop it defaults to light status = 0 and clears the pixels. I turned that if/else into an if/if. So technically there’s no default command for the lights anymore, which got rid of the stutter

Lightbox R0

AC Power Port

https://www.amazon.com/button-Adapter-Connector-Socket-MXRS/dp/B082ZFRV1B/ref=pd_day0fbt_img_sccl_1/144-7350682-5806604?pd_rd_w=7X3VD&pf_rd_p=bcb8482a-3db5-4b0b-9f15-b86e24acdb00&pf_rd_r=SX1JSAA9SA8365BYANJM&pd_rd_r=2a07e6ad-f631-4baa-9e80-f91427ab0b17&pd_rd_wg=Swye7&pd_rd_i=B082ZFRV1B&psc=1

Comes with a switch! $8

PCB

Could design a PCB that has a buck converter, the necessary circuits, and the EPS32 in it all in one

The weakest part of the circuit right now is the fact that all the power coming from the power supply is carried to the breadboard by a single jumper

So the best way to fix that is to get thicker wires, or more wires

If i had a PCB, I could make some large heat dissapation zones and then have similar screw down terminal clamps

I could probably do that with a proto board

Cables

Thicker cables are needed

Maybe 16AWG to be safe?

https://www.amazon.com/dp/B079CFZZYS/ref=sspa_dk_detail_5?psc=1&pd_rd_i=B079CFZZYS&pd_rd_w=yyeqR&pf_rd_p=0c758152-61cd-452f-97a6-17f070f654b8&pd_rd_wg=esIgs&pf_rd_r=0Z2ETXA7DD813T1W40HE&pd_rd_r=c0528a0e-5856-4ea6-b460-eca03ea59510&s=electronics&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyUEJPMVRRWkFBQU1QJmVuY3J5cHRlZElkPUEwODg0OTQyM01RREdGUVoyQlhWSSZlbmNyeXB0ZWRBZElkPUEwOTg0NzgwM1ZTSjlNV0xNVERNTyZ3aWRnZXROYW1lPXNwX2RldGFpbCZhY3Rpb249Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU=

Also need some terminal blocks to clamp down in that case

The power rails only go to the strip and the ESP32 anyway!

More specifically the buck converter

C++

https://www.cplusplus.com/

https://isocpp.org/

Unity

AoE

Prusa Tuning

Going through the teachingtech calibration guide, but maybe this time it’ll stick hahahhahahahaha

Running GCode over USB to the printer to minimize crouch time

It actually looks like the printer gets worse the more I tune it. more prusa magic?

PID Tuning

The Prusa has a built in PID Tuning button, so ez

First Layer Tuning

Starting with all the default settings

Bed Dimensions 210 x 210

Temps 210/60

Printer is Direct Drive so

1mm Retraction

60mm/s print speed

Z-Axis Calibration

Started at -1.225

Distinct Ridges

-1.000

Distinct Gaps

-1.125

Seems to work great!

Confirmed, -1.125 is just about perfect, according to the results I’m seeing on the test pattern

Correction, Print Dimensions are

X: 250

Y: 210

Text Embossing

FreeCAD

Go into Draft mode

Create the text string

Select the font file

Select the anchor point (bottom left)

Then click the button on the top bar to convert the SuperString into a Sketch

Apply that Sketch to a Body

Pad it onto ANOTHER PRE-EXISTING BODY so you don’t get a “multiple solids” error

Enjoy

For reversing the text, make sure the pad direction is inversed, and then pocket the text

Color Changing

It’s actually super easy to add a color change prompt

Just Slice the STL, and then navigate to the first layer that should have the color changed, and then click the plus icon next to the layer select node on the vertical line

Project Idea

Flashfire Box

It’s a box

And there’s a metal grate floor

And there’s lighters at the bottom

Well not normal lighters, just the lighting mechanism, and they’re bigger

and they’re electronically controlled to make a brief flash of fire

burns off the stringies on 3D prints

Also cool to flash some fire

Minecraft Server

https://www.bisecthosting.com/blog/craftbukkit-vs-spigot-vs-paper/

Paper is fastest

https://www.bisecthosting.com/blog/five-essential-client-side-mods-for-minecraft/

https://apexminecrafthosting.com/top-10-minecraft-plugins/

WorldEdit

Dynmap

EssentialsX

Clearlagg

Holographic Displays

Factions

LuckPerms

mcMMO

WorldGuard

SilkSpawners

Timber

Vault