K: 5/23/2022 – 6/5/2022

L: 6/6/2022 – 6/19/2022

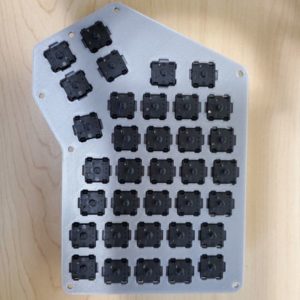

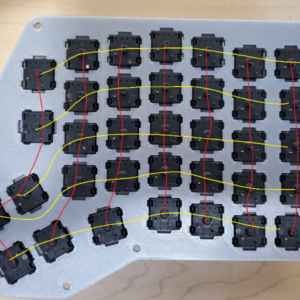

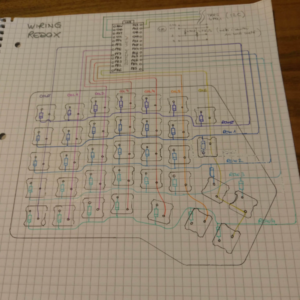

Summary: Now on Hiatus! I’m moving to Washington so lab time has decreased considerably and will stay down for the next 2 months at least. I printed out a Redox Mechanical Keyboard, put in some black switches, ordered some Matcha Keycaps, and then hand-wired and soldered together the left side. I put in an Arduino Pro Micro, flashed the firmware, and it worked first try. Pretty gratifying!

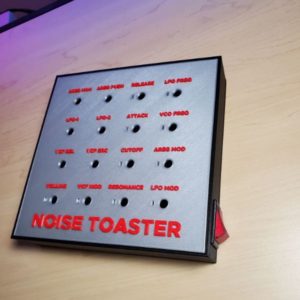

I also built another Noise Toaster with the new printed color change text and a new design that uses bolts instead of a slide mechanism. It looks and feels way better. I recorded a timelapse of the prints, and recorded/streamed the part picking, soldering, and testing process. That’s about the extent of what I’ve got going on right now. Once I get set up in the new place I’ll handwire the second half of the keyboard, make another synth to give out to itvlo, and then move onto some new stuff. I also made a new soldering iron station but I don’t have any pictures of it. It’s very nice though.

I have been having more new project ideas and have sketched a few out recently too. No shortage of stuff to work on once we’re back.

Komodo/Lizard

Komodo Modo

Thaw Update

Smash Briefcase

Materials Rough

S1-new switch

Briefcase

80

LCD Screen

66

GCC Adapter

40

Battery

30

Misc Backend

HDMI Ribbon Cabling

Simple BMS/PSU

Speaker Wiring

Foam/Obscura

Filament

Nuts/Bolts/Screws

Power Cables

Extension Cord

60

Switch Speaker

20

Bluetooth Speaker

30

Nintendo Switch

300

2x GCC

92

Total

718

S1-existing switch, no controllers, no speaker

Briefcase

80

LCD Screen

66

Switch Dock

60

GCC Adapter

40

Battery

30

Misc Backend

HDMI Ribbon Cabling

Simple BMS/PSU

Speaker Wiring

Foam/Obscura

Filament

Nuts/Bolts/Screws

Power Cables

Extension Cord

60

Switch Speaker

20

Bluetooth Speaker

30

Total

386

Layout

Briefcase

Enough depth to hold monitor, monitor framing, and obscure some cabling

Plus Speakers and some LEDs probably

Enough bottom depth to hold the switch dock, battery, gcc adapter, and 2 gccs

$80

18 x 14.25 x 5″

https://www.amazon.com/Vaultz-Locking-Laptop-Black-VZ01216/dp/B00153BIMA/ref=pd_rhf_se_s_pd_sbs_rvi_sccl_2_1/147-7784981-8143038?pd_rd_w=TBjYZ&content-id=amzn1.sym.80dc3982-f1a9-4e70-830e-7a37a0660538&pf_rd_p=80dc3982-f1a9-4e70-830e-7a37a0660538&pf_rd_r=DW4XXGQ0H2DC245S6J6G&pd_rd_wg=Tsg9W&pd_rd_r=313665bd-5c1f-4e1a-a037-d517cb9cd5a3&pd_rd_i=B00153BIMA&psc=1

LCD Screen

1080p

15.6″

$66

https://www.amazon.com/BRIGHTFOCAL-A515-51-58HD-Non-Touch-WUXGASlim-Replacement/dp/B07NQP46SR/ref=sr_1_14?crid=1TVMFSPDBE8TP&keywords=1080p+replacement+lcd&qid=1655063118&sprefix=1080p+replacement+lcd%2Caps%2C127&sr=8-14

Monitor Frame/Mount

3D Printed

Embedded into the Briefcase

Switch Dock

Official Nintendo Switch Dock

$140

https://www.amazon.com/Nintendo-Switch-Dock-Set/dp/B06ZZ6FGGL/ref=sr_1_6?crid=12MRGYQDUL4QV&keywords=nintendo+switch+dock&qid=1655064883&sprefix=nintendo+switch+do%2Caps%2C166&sr=8-6

Nintendo Store

$60

https://www.nintendo.com/store/products/dock/

$75

Genki Dock

Outputs 30W of USB-C power for the switch

https://www.genkithings.com/products/covert-dock

GCC Adapter

No off brand shit

$40

Nintendo branded GCC adapter from Japan

https://www.amazon.com/Nintendo-GameCube-Controller-Adapter-without-English/dp/B07HC15QNZ/ref=sr_1_4?crid=2A90GTI9XPW06&keywords=nintendo+switch+gamecube+adapter&qid=1655064722&sprefix=nintend+%2Caps%2C149&sr=8-4

Power Wiring

Nintendo Switch

$300

https://www.amazon.com/Nintendo-Switch-Neon-Blue-Joy%E2%80%91/dp/B07VGRJDFY/ref=sr_1_3?crid=3IGB438770N2O&keywords=nintendo+switch&qid=1655066234&sprefix=nintendo+switc%2Caps%2C162&sr=8-3

Audio

Speakers for Smash, hardwired

Either attached via the Aux Port or attached via the HDMI ribbon cable splice

$20

Separate from the switch speakers, another Bluetooth Speaker

for player spotify

Permanently wired into the battery grid as well so it never needs to charge

Would need a power switch for it though

$30

Control Wiring

HDMI to Ribbon Cable

Around $15

https://www.amazon.com/Arducam-Extension-Module-Raspberry-Specific/dp/B06XDNBM63/ref=sr_1_4?crid=10VRVPR43WUUP&keywords=ribbon+cable+to+hdmi&qid=1655064371&sprefix=ribbon+cable+to+hdmi%2Caps%2C131&sr=8-4

GCC Storage x2

Like the adapter, make sure it’s nintendo brand

no off brand shit

This exact listing

$46

https://www.amazon.com/Nintendo-Controller-Super-Smash-Bros-switch/dp/B07HC2F97Q/ref=sr_1_3?crid=14E305J3U7NQP&keywords=nintendo+gamecube+controller&qid=1655064778&sprefix=nintendo+gamecube+controlle%2Caps%2C131&sr=8-3

Battery?

DC Battery would have to match power characteristics for both the switch and the monitor

Idk the tolerance level of the switch power converter, but i know the screen and the switch would both take DC, right?

Laptop battery should be fine in that case, since the laptop runs the screen and a computer already then that should work

Power Consumption of Switch

Lithium-ion battery/4310mAh

TV mode

Playing a game: Approx. 7W

Watching a video: Approx. 6W

On the main menu: Approx. 3W

Sleep mode: Approx. 0.3W

Power off: Approx. 0.3W

Monitor 15.6″ LCD/LED: Around or Under 20W

Laptop Battery?

$20-50

Around 5000mAh

Power draw expected around 30W for switch and 20-100W for screen

https://www.amazon.com/Replacement-593553-001-Presario-Pavilion-DV3-4000/dp/B073VJVH1N/ref=sr_1_3?keywords=laptop+battery+replacement&qid=1655064450&sprefix=Laptop+battery+re%2Caps%2C121&sr=8-3

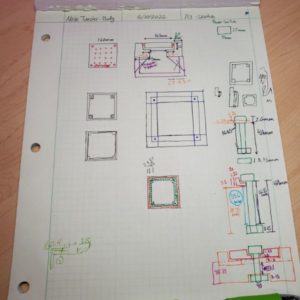

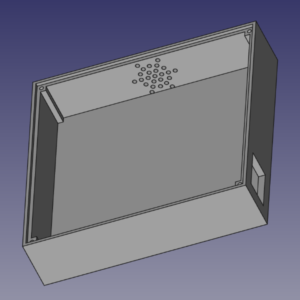

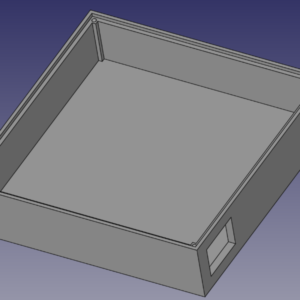

Noise Toaster

Casing

Decided I want to go with a bolt-on design for the front panel instead

It’s mechanically simpler for everyone involved (me and the user)

It means that if someone wants to get into the case, either to change the 9V or to troubleshoot wiring, they can do that simply and easily

Without having to rely on a sliding panel

This also means that The sliding panel doesn’t exist, and can’t possibly fall away, get damaged, or otherwise interfere with the function/safety/aesthetic of the box

I will need to chamber the harsh edges of the box when I do the final print as well

Currently in the process of designing recessed pockets that can hold an M3 nut and bolt without bulging out and scuffing the outer profile of the box

Once that’s done, I need to probably reprint the Synth Front Panel with the holes, and make sure it’s thick enough to handle a slight pocket for the exposed nut, or maybe not, maybe it can just poke out, who cares really. As long as it’s not scratching whatever surface its on when it’s on its back that’s fine with me

The depth of the box will now be limited by the length of the M3s however

The ones I have are only 20mm, which is too small

Simple Solution, Get longer M3s

30/35/40/45/50mm SS M3 (200pcs) for 12.00 on amazon

They’re silver so they might match the galaxy silver filament I’m using. If not, nbd

Old box was 40mm so that should solve that problem pretty nicely

Gonna stick with hot glue for mounting the PCB. nobody needs to see that, and this is a good use case for the powers of Hot Glue

I should look into that UV Curing Epoxy though, I heard it was (super good)

I also need to test printing for the Power Switch, and Make sure its obnoxiously large profile fits cooperatively into the case

So Current Steps to Completion are

Purchase more Connectors/Pots/Switches

Finish SOP Dimensions for M3s on my Printer

Test pocket depth on a 2.5mm slab for front panel

Add Pockets to Front Panel

Redesign Body with Pocket Frames, Power Switch, and Chamfers

Set up 3D Printing Timelapse

Print Front Panel [R]

Print Body [R]

Assemble without Electronics

Confirm it’s good

Setup Soldering Recording Timelapse

Assemble Electronics [R]

Test Synth Board

Hot Glue Functional Synth Board to Case

Mount Front Panel Interfaces

Button it up

Take Pictures [R]

Active Projects & Objectives

Noise Toaster

Design New Case

Assemble New Board

Record Video

Lightsbox

Try not to break it or burn the house down

Start Designing a PCB for it

Start Designing a new box for it

Solder Station

Finish Making design changes and print

Put it all together and start using it

Breadnet

Harden

Project Notes

Noise Toaster

New Body Design

Mounting Holes

The length of an M3 bolt refers to the length of the shaft, not the absolute length of the piece

M3

Shaft

2.95mm

Hex Nut

5.55mm Hex OD

2.6mm Depth

Bolt Head

5.60mm Circ OD

3.15mm Depth

Previous case has a depth of 40mm inclusive

Designing around a 40mm M3 bolt that runs through the entire body of the print

Power Switch

Speaker

Front Panel Design

Front Panel should now rest on top of a lip from a slightly smaller square

The front panel dimensions are 160x160mm

2.5mm lip on all sides means an internal dimension of

155x155mm

Which is attached to a

Parts Ordering

Casing

Carve a hole for the switch dimensions

Design a slide panel that slots into the corner of two walls for the 9V battery

Use the 9V battery holder, extend it to match the length of the battery, and give it a bottom so the battery rests flush in place

Leave the battery head facing out of the casing with enough room for the connector, and enough room for the slide

Test notched slides until you get a good method for them

Power Switch Measurement

rectangular hole inside a 2.5mm thick slab

Measured Dimensions:

26.94mm

Snap Tabs: ~1.4mm

21.30mm

Test Dimensions

29

22

29×22

5mm buffer on all sides

39×32 print area

Too Small

Final Dimensions

41x32mm print area

31x22mm switch gap

Slide Panel Tests

Vertical Printed

2.5 thickness slide

2.5 wide gap

doesn’t fit, spreads the frame

2.75

fits perfectly. pretty satisfying, but there’s not enough friction/grip. the slide can shift around in place

2.625

This is the compromise. It still slides with ease but there’s enough friction, and it doesn’t spread the frame

Add ONE EIGHTH of a millimeter for slides

Horizontal Printed

I have to rerun these tests because the overhang creates issues

2.625

isn’t enough

2.75

Front Panel Slide Rails

Front Panel Dimensions

160mm Across

160mm Deep

2.5mm Thick

Slide Rail Dimensions

165mm x 165mm

7.5mm tall with a 2.625 tall notched vertically centered, cutting in 2.5/5mm deep

Front Panel M3 Bolt Check

Measurements

M3 Bolt OD

5.38mm

Hexagon

>

5.55m Hexagon Diameter

M3 Bolt ID

~2.6-2.75 mm?

Check Spec

Shaft/Thread Diameter

Consistently measures around

2.93, 2.94mm

Consistent with M3 (3mm)

Will make a snug shaft of 2.90mm

Works, but inconveniently snug. Try 2.95

Bolt Head Height

3.04mm

>

3.15mm

Bolt Head OD

5.45mm

>

5.60mm (larger than hex)

M3

Shaft

2.95mm

Hex Nut

5.55mm Hex OD

6.41mm Hex OD

corner to corner

2.6mm Depth

Bolt Head

5.60mm Circ OD

midpoint to midpoint

3.15mm Depth

Front Panel Pocket Depth

Front Panel is only 2.5mm thick

I can print a small 2.5mm slab and have four pocketed corners of varying depths to see which works best

0.5

1.0

1.5

2.0

Those are really the only options

There might be an optimal of 1.25, so I’ll do that in the middle too

1.25 is the move

Or really it would be better to just do a strip instead

Solder Station

Tool Cart

The six holes for the additional irons are a little loose, I’d like to print them a little stiffer so they don’t wobble around. The rest of the holes are fine as is

I’m experimenting with adding a shaft coming outside the back that can act as an axel for the spool of solder wick. printing out some 8mm shafts and slots to see how they fit

I could drill a hole and bolt it in, but I think a more elegant solution would be to print my own shaft and cap

Iron Holder

There’s a little too much wobble in the iron holder itself

To fix that though I would need to extrude some wider diameter arc at a plane, which might be difficult. Otherwise it works great and it turns out the first cm or 2 of the metal isn’t hot. It shouldn’t really be dangerous or painful until the extended, thicker part of the shaft

I cut a sponge using a kitchen knife and it fits great. I’m thinking of hot glueing it, but I’m going to hold off on that until I do a reprint, since it looks like that’s where this is going

For the TS-80 logo, I’m thinking of padding that out of the picture and then adding an eein.info instead

I cannot get rid of the existing logo because of the way I import STLs and convert them into bodies in FreeCAD.

The shape is too complex and it lags my computer. I’m sure there’s a way but it’s not that big of a deal to me.

With that in mind I might just end up drilling the existing piece after all

Wool Pit

Cut the amount of copper wool I have in half and it’s the perfect amount to stuff in there

No other changes to make here

New Helping Hands

Got a new Helping Hands set. They are superior.

Mechanical Keyboard

Printed out both sides of a two-piece mechanical keyboard. It came out nicely and is pretty satisfying to handle.

Angel got me a pack of 120 black switches a while back and they don’t fit into my current keyboard but fit nicely into the printed frame

keycaps are arriving today, but I don’t have a microcontroller ready for it, nor have I really looked into the wiring yet.

Resources

Wiring Guide+Other Resources

https://www.crackedthecode.co/a-complete-guide-to-building-a-hand-wired-keyboard/

https://geekhack.org/index.php?topic=87689.0

Teensy Official

https://www.pjrc.com/store/teensy.html

Redox Layout Official

https://thangs.com/designer/ZackFreedman/3d-model/Redox%20Handwire%20Mechanical%20Keyboard-10464

https://www.thingiverse.com/thing:2704567

QMK Official Wiring Guide

https://github.com/qmk/qmk_firmware/blob/master/docs/hand_wire.md

TRRS

https://www.cablechick.com.au/blog/understanding-trrs-and-audio-jacks/

Keyboard Test

Sam Sattler

Article

Table of Contents

Disclaimer

Global issues

World hunger

Air pollution

Is renewable energy the solution?

Renewable energy

Electric cars

Carbon capture

The biggest issue

Renewable energy’s secret ingredient

What actually are they?

Rare earth metals aren’t rare at all

Civilian use

Military application

Green energy

The supply issue

Destroying our a planet in order to save it

A plan to destroy the ocean

Asteroid mining

Why asteroid mining

Asteroid mining methods

TransAstra’s plan has its own issues, but the concept is generally solid. Their plan is to make a gas station in space both on the moon and in orbit around it so that consumer rockets can refill after spending the majority of their fuel leaving earth orbit.

The fuel comes from mining asteroids, but more specifically extracting volatiles from ice-laden asteroids. The unprocessed material gets sent back to the moon so it can get refined into fuel. but to move back to the station, these automated worker bee drones jettison water out the back as steam to produce the thrust.

Something your article doesn’t really address is incoming freshwater scarcity. water wars are real and if the water threatens to run dry people won’t care how much oil they burn. this is a more sensitive pain point you should look into more.

Along with that, as we move into space, we’re going to have the same issue. There are a finite number of asteroids, and a finite amount of ice in the solar system. If we push steam out the back of thousands and thousands of automated drones, we are permanently reducing the total amount of water we have access to. whether that water is used to quench thirst or is captured in lifeforms doesn’t matter, we lower our own scope.

turns out this is wrong. there’s far more water offplanet than on planet in the solar system

If we had better ionic thrusters we wouldn’t have to worry about wasting water, but it’s similar to the problem you describe with current renewable energy sources, they require obscure materials and manufacturing and don’t perform well

Space manufacturing

nitpicky, but the cost to orbit says it dropped 5000%. things can’t drop 5000%

did you mean it costs 1/5000th of what it did before? then say 99.98% price reduction

My plan for a better future

Nuclear energy a temporary solution

see fusion vs fission below

Asteroid mining effects

what’s more important, expanding into space, switching to renewable energy, or accelerating innovation? it seems like they all go hand in hand, but there are tradeoffs for prioritizing one over the other.

consider Mess Before Mars: if we don’t create a sustainable civilization-system before we go to mars, it won’t happen on mars either

offworld manufacturing means you should consider that 51% of all resource extraction and manufacturing will be done off-planet and shipped down. Many, many more things will be entering the planet than leaving.

Similarly, all planet’s atmospheres eventually thin out over time as gas expands into the vaccuum of space. There is a non-zero argument for releasing CO2 into the atmosphere in order to keep the air thick enough to breathe. It’s something we would have to do excessively to terraform a planet like mars

Carbon neutral energy

carbon isn’t the biggest issue

you’re kind of circling on the issue of free energy with this and the farm thing

it’s why people chase nuclear fusion, which you don’t really mention in the article. does your stance on nuclear as a long term energy solution account for the differences between fusion and fission?

if energy was “free” then we could just run carbon capture machines, extract the CO2 from the air and condense it back into gasoline. but energy won’t be free

even if we have nuclear fusion reactors that produce 100x the energy capacity we require, the logistics involved in distributing that energy mean that energy will never be free. in an abundant future, long-term, it’ll just be cheaper the closer you get to the source

Have you heard of solar power satellites? Solar power works much better in space and it’s possible to beam the collected energy back down to the surface from a satellite much like you would send a radio signal. Along this line is a Dyson Swarm/Sphere.

Reversing environmental damage

should develop further ideas about environmental damage/climate change

what we’ve done can’t necessarily be reversed. for one, this is a mass extinction event

second, there’s no way for modern civ to continue processing as much material and energy as we are without affecting the environment at large, even with 100% carbon neutral energy systems

the only remaining option is for us to start stewarding the environment ourselves. unfortunate but there won’t be much more “virgin land” moving forward

Solving world hunger

Farm idea doesn’t make sense

See SFIA

One large farm isn’t useful

Would it be monoculture? one crop? viral contagion wipes our the planet

centralized systems usually have singular points of failure too

what’s getting grown? livestock upcycles food into something more nutritious

if you could convert grass into steak, you would buy that machine

crickets

Closing thoughts